Night Watch Knives has been in operation since February 2017 under the sole authorship of Alex Harrison, voting member of the Knifemaker’s Guild. From the utilitarian Mule to the lavishly appointed Gary Plauche Bowie, every knife is hand made with pride in Kansas City, Kansas. Each blade that leaves the workshop is built without the use of jigs, fixtures, or computer assisted design.

Materials and construction methods are chosen based on documented performance track records rather than industry fads and trends. Heat treating and milling operations are performed in-house and without technical compromise. Every aesthetic choice is complimentary - but ultimately secondary - to the function of the knife.

The slogan – Light, Comfortable, Capable – is a design philosophy that is religiously adhered to. Each knife that leaves the workshop must be lighter in the hand than it appears, comfortable in every useful grip the user may require, and engineered from conception to finished product to be a performance tool first and foremost.

Signature Methodology

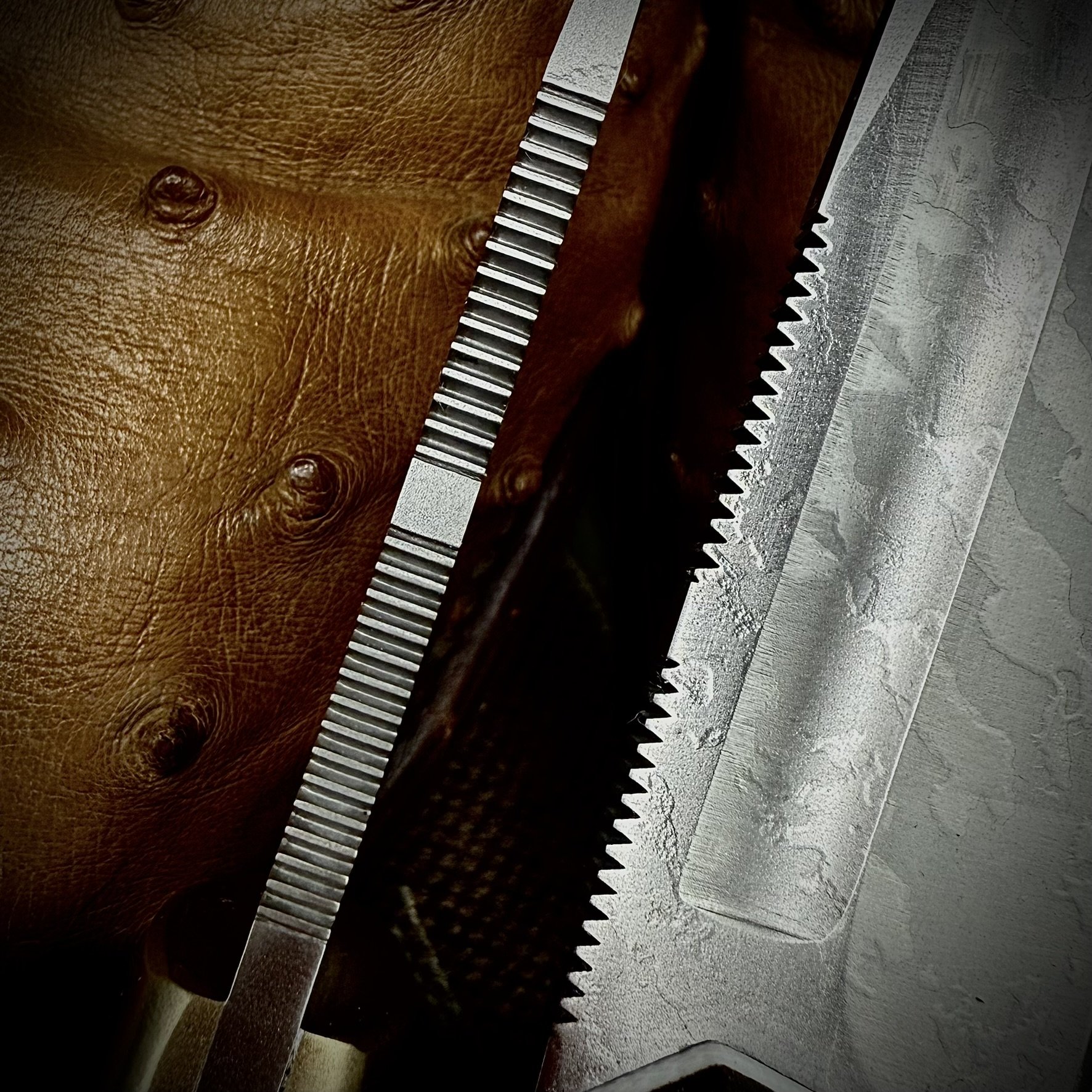

War Wash

War wash, in all of its subtle variations, is a chemical etch which is applied to a blade that has already been ground to a perfect satin. It is not pattern welded “damascus” steel, but a surface treatment that can be applied to a high-performance mono-steel like CPM-Magnacut. If you look closely at a war washed blade, you’ll see that it appears to have “highs” and “lows.” The low points are where the in-house acid blend (ferric chloride and distilled water) has eaten away at the steel. This is a labor-intensive process that involves a series of carefully timed steps and the use of a finesse-driven hand application of a pattern that is unique to each individual knife. The easiest way to clarify the nature of this finish is that the finish is not a coating. It is not on the steel. It is the steel. It is no easier to damage or abrade this finish than it would be to mar a raw satin finish on the hardened CMP-Magnacut steel itself. This makes it the most durable blade finish on offer from Night Watch Knives, in addition to being our signature look.

Free-hand Grinds

While there are many valid, widely accepted methods of machining or grinding a blade, the Night Watch Knives workshop exclusively utilizes free-hand grinds. Every blade is taken from blank to finished work product by hand, by a craftsman standing at a belt grinder. With rare exception, our blades are hollow-ground on a 6” radius grinding wheel, allowing for thin edges and dramatic hollows on thinner blade stock. Generally speaking, 0.125” thick bar stock is used for our blades.

Blasted G10

G10 is a widely available commercially manufactured synthetic material composed primarily of fiber glass and phenolic resin. It is impressively light and as close to indestructible as you could want it to be. G10 takes a beautiful polish at higher grits of finish, but where it really shows its value is after a heavy bead-blasting treatment. This removes the surface resin and exposes the individual layers of fiberglass. In it’s resin-impregnated state the fiberglass is not an irritant, nor is it fragile. The texture created by blasting the G10 offers a beautifully tactile, sure grip regardless of any perspiration or other moisture that may be present. The G10 used by Night Watch Knives is proudly manufactured by Current Composites at their plant in East Haven, Connecticut.

Tapered Tangs

A feature commonly touted by custom knife shops and rarely – if ever – duplicated in a factory or production setting, a tapered full tang on a knife accomplishes two tasks. First and foremost, this is a spectacular weight reduction measure with a noticeable difference in weight and weight distribution. The more subtle but arguably more valuable feature of a tapered tang is the aforementioned shift in the knife’s center of balance. By tapering the tang, the center of balance is moved to the middle of the knife, just underneath the user’s index finger and the ricasso. When paired with a hollow grind, this is the single biggest contributing factor to the fact that every knife produced in the Night Watch Knives workshop feels inordinately light.

Handle Profiles

Great care is taken in the design and execution of each handle. Generally speaking, Night Watch Knives feature a neutral handle profile with a slightly more aggressive downward angled blade. This is sometimes referred to a “forward angle of attack.” In addition, the attached handle scales are shaped and contoured by hand to eliminate the presence of any hot spots and allow for the comfortable use of a multitude of alternate grips. Our handles also feature an ovoid cross section which allows the user to effortlessly “index” the knife and be aware of where the edge is relative to the position of their hand without the need to look at the knife.

Guard/Choil Construction

The lesser the distance between the user’s index finger and the cutting edge, the greater the control the user has over the edge. This is essential for tight control over fine motor skills cutting/shaving tasks. With rare exception, our blade profiles are designed to minimize the amount of “wasted space” between the user’s index finger and the cutting edge. This is done while maintaining the necessity for some sort of protection between the user’s hand and the edge, as well as the requirement for a sharpening choil to allow for cleaner, more efficient edge maintenance. By integrating the “self guarded” handle scales to the rear of the sharpening choil and a plunge cut that begins at the choil’s apex, most of our patterns are designed to have less than a quarter of an inch of “Dead space” in the ricasso.

Thumb Jimping

The thumb jimping applied to our patterns is created by hand using a checkering file. This creates a very fine pattern compared to machined jimping. It allows for positive kinetic contact with the spine without creating an unnecessary hot spot. While the checkering file is used to gently radius the spine of the knife, our users have found that the textured section of the spine functions very well for the purposes of striking a ferro rod.